|

|

About iCT-M

Implementing ICT-M

Real-Life iCT-M Implementation

|

|

|

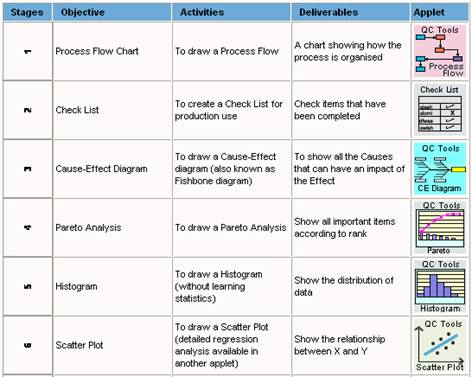

The real-life implementation requires application of many process improvement tools

to identify, execute and close projects. In modern businesses, these tools are nearly

always computer aided and while much excellent software exists, many are independent

applications that must be managed in terms of data file storage and retrieval. In

most software, files created by the software are saved as in some directory. This

directory is often only available to that particular user. Although network directories

may ease this file sharing somewhat, the data interchange is still lacking. When

a project requires several application tools (e.g. Pareto Analysis, Histogram, etc.)

tools undertaken by different team members are saved in their respective hard disks.

For a manager, this means having to ask for project status from the team members.

In fact, the manager has little say over the management of the data or knowledge.

The inability of management to control this knowledge is a great loss to companies.

In future undertakings, knowledge lost with the movement of employees has to be

relearned - reinventing the wheel, while the competition marches on. |

|

|

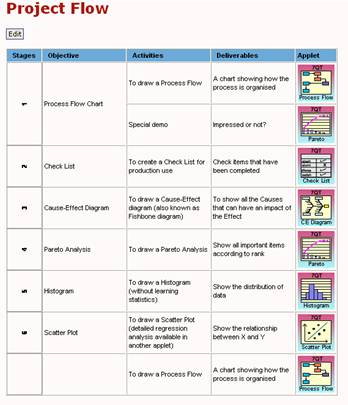

The new iCT-M software for productivity and quality improvement works rather differently.

With iCT-M, files and data are managed collectively and without the user having

to remember where those files and data are store. iCT-M allows practitioners to

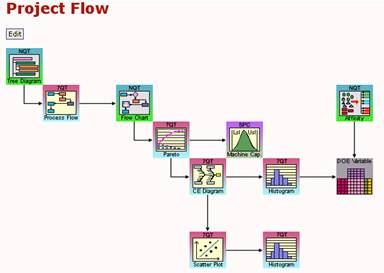

carry out projects in two distinct ways: checkerboard or storyboard. Project leaders

can conduct several projects and open each project element as a dynamic applet.

Consider a team working on Reducing Forming Defects. There are many tools and techniques

which are required in this problem solving process. These activity tools organized

as a checkerboard may look as follows. |

|

Checkerboard Project Flow |

Storyboard Project Flow |

|

|

|

The reader may recognize many of these icons. Icons are related to an application

so that clicking on a icon invokes that application. With either of the checkerboard

or storyboard. structures, practitioners need not worry about file and data storage

or retrieval. Additionally, the project flow of applications is unlike any other

software. With iCT-M's structure, the natural progression is inherent and practitioners

can see the logical development of a project from its early stages. With iCT-M new

icons can be inserted and unwanted icons can be deleted. This dynamic system allows

practitioners to modify their project plan as new information is received. |

|

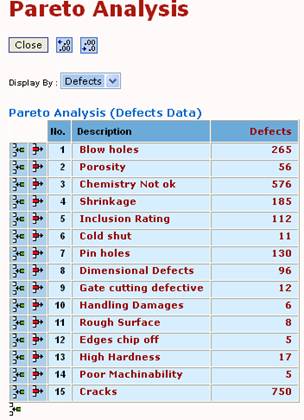

Once a board is created, the user can click on an applet to invoke that tool.

For example, clicking on Pareto will open a dialog page as follows. This page has

an insert/delete row function. The user enters as many rows as possible and the

number of defects or other quantity. There is an option to consider the Pareto Analysis

by the number of defects or by cost. Once the user clicks Close, The Pareto chart

is drawn as follows. |

|

|

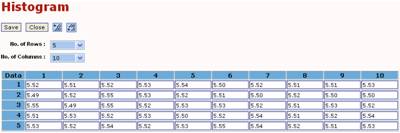

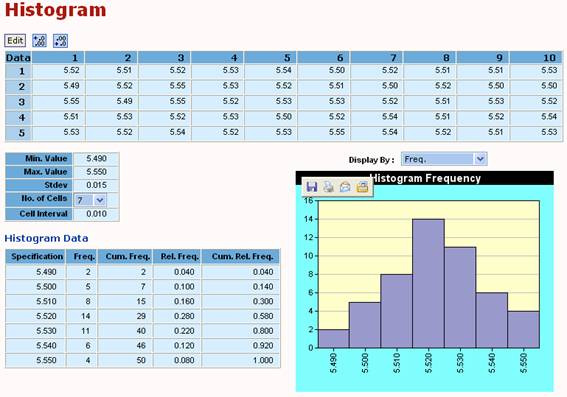

After the Pareto Analysis is completed, the user can move to the next applet by

clicking on another applet in the project flow, such as the Histogram, shown below.

Once again, clicking on the Histogram icon invokes the Histogram application. An

appropriate dialogue page appears and the user need only enter the data.

|

|

|

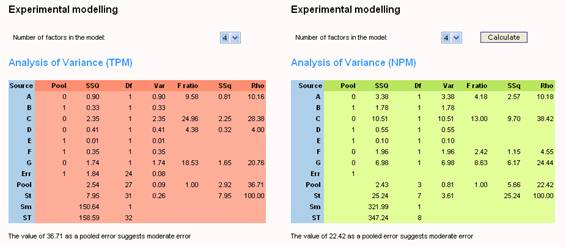

At first sight this series of activities may appear somewhat insignificant considering

much software that can perform very detailed data analysis. However, consider for

example, how a very ardent user may conduct a Design of Experiments, all be it,

a simple 2^3 (or otherwise an L8 (2^(7-4) i.e. 1/16 fractional factorial of 2^7).

Already the jargon may put most users into a state of limbo. This is precisely where

iCT-M holds the rein. iCT-M provides 21 pages of simple step by step pages that

takes the user through the experiment without demanding (almost) any statistical

knowledge. Nowhere does iCT-M ask for the confounding relations, number of replication

or repetitions. Even the best software in the field does not consider the quality

loss function when in fact any basis of experimentation, or indeed and quantification

of experimental success, must involve a bottom-line measure, almost invariably,

COST! Not many software do this. Unlike iCT-M. |

Conducting the Experiment

Conducting an Analysis of Variance

Displaying the process improvement

|

|

Because of the complexity of most applications, and the mathematic or statistic

detail required to perform most productivity and quality improvement tools and techniques,

most users are not excited about conducting say, Measurement System Evaluation (MSA).

With iCT-M, anyone who understands the basics of what MSA is about can conduct a

study of MSA. Indeed, with over 150 tools and techniques, including 7 QC Tools,

New QC Tools, Advanced QC Tools, Voice of Customer, Quality Function Deployment,

Failure Mode Effect Analysis, Statistical Process Control, Advanced Statistical

Techniques, Measurement System Analysis, Hypothesis Testing, Design of Experiments,

Control Plans, Dynamic Control Plans, Production Part Approval Process, etc. Clearly,

iCT-M is the new standard of productivity and quality improvement tools and techniques. |

|