|

|

Analytical Techniques

ANALYTICAL TECHNIQUES

|

By Dr. Nicolo Belavendram

Design and Production, Faculty of Engineering, University of Malaya

|

|

For APQP:

Note that while the phases 1-4 have input - output relationships, this is not usually evident as a direct line.

Appendix B in the Automotive Industry Action Group's, (AIAG) APQP Reference Manual suggests many different tools and techniques that may be used in APQP.

For Six Sigma:

Note the DMAIC methodology is not usually evident as a direct line.

Many different tools and techniques may be used in Six Sigma.

To the extent that direct lineation cannot be drawn the process is subject to inter-linking. Thus, if one document is updated there is every change that another related document is not updated. Here, iCT-M software can be of great assistance.

Many of these tools and techniques require much training and resources. With iCT-M, employers can empower employees to tackle a large number of applets (tools and techniques) including the following:

|

7QCT: Seven Quality Control Tools 7QCT: Seven Quality Control Tools

Process Flow Chart, Check List, Cause-Effect Diagram, Pareto Analysis, Histogram, Scatter Plot, SPC

|

NQCT: New Quality Control Tools NQCT: New Quality Control Tools

Advanced Flow Chart, Affinity Diagram, Characteristics Matrix, Organization Chart, Tree Diagram, Force Field Diagram, Before After Graph, Pareto Comparison, Simple Gantt Chart, Gantt Chart

|

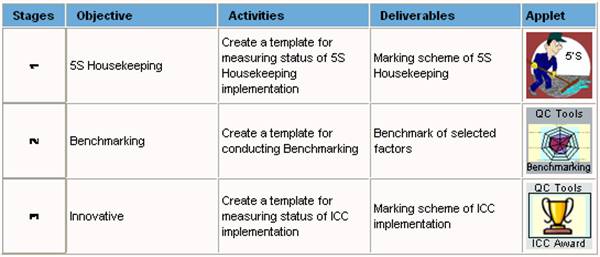

AQCT: Advanced Quality Control Techniques

AQCT: Advanced Quality Control Techniques

5S Housekeeping, Benchmarking, Innovative Creative Circles

|

VOC: Voice of Customer

VOC: Voice of Customer

Things Gone Right, Things Gone Wrong, Voice of Customer,Kano Analysis

|

QFD: Quality Function Deployment QFD: Quality Function Deployment

Quality Matrix (shown left below), Function Matrix (shown right below), Quality-Function Matrix, Production Matrix, Concept Selection, Service Matrix

|

FMEA: Failure Mode Effects Analysis FMEA: Failure Mode Effects Analysis

Product, Process, Product & Process, Production

|

SPC: Statistical Process Control SPC: Statistical Process Control

Machine Capability, Pre-Control Chart, XBar-Sigma Chart, XBar-Range Chart, XInd-RMov Chart, XMov-RMov Chart, Median Chart, d Chart, p Chart, c Chart, u Chart

|

AST: Advanced Statistical Techniques AST: Advanced Statistical Techniques

Frequency Chart, Sampling by Code, Single Sampling Plan, Double Sampling Plan, Acceptance Sampling, Online Quality Control, Weilbull Curves, Constant-Wear, Wear-Out, Failure Pattern, Accelerated Tests, Product Reliability Studies

|

MSA: Measurement Systems Analysis MSA: Measurement Systems Analysis

Bias, Linearity, Stability, GRR (Short Term), GRR (Long Term), GRR (Anova), GRR (Attribute), Measurement System Evaluation

|

HYP: Hypothesis Testing HYP: Hypothesis Testing

z-Test, t-Test 1 Sample, t-Test 2 Sample, t-Test Paired, One Proportion, Two Proportion, Anova 1 Factor, Anova 2 Factor, Chi-Squared Goodness Of Fit, Chi-Squared Test Of Independence

|

DOE: Design of Experiments DOE: Design of Experiments

Variable, Idle Column, Nested Factor, Operating Window, Combination Column, Attribute

|

CPM: Control Plan Methodology CPM: Control Plan Methodology

Prototype Control Plan, Pre-launch Control Plan, Production Control Plan

|

DCP: Dynamic Control Plan DCP: Dynamic Control Plan

Proto-type Dynamic Control Plan, Pre-launch Dynamic Control Plan, Production Dynamic Control Plan

|

PPAP: Product Part Approval Process PPAP: Product Part Approval Process

APQP Checklist, FER Checklist, Retent-Submit, Part Submission Warrant, Appearance Approval Report, Dimensional Results, Material Test Results, Performance Test Results, PPAP

|

|