|

|

QYP - Quality Yield Productivity (Multi Line)

QYP - Quality Yield Productivity (Multi Line)

QYP - Quality Yield Productivity (Multi Line) - Quality Yield Productivity is a process of calculating the amount of accepted products from the given input to the machine/machines or process/processes.

|

QYP - Quality Yield Productivity (Multi Line) - Enterprise

|

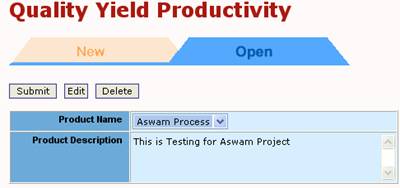

1. Select Product

|

Quality Yield Productivity (Multi-line) is a Quality, Yield and Productivity tracking system in which child parts and assembled into parent parts. Parent parts are in turn assembled into grand parent parts.

Select Product:

The Select Product menu allows the user to create New or Open existing named product lines. The Product Description allows a short description of the production line.

|

2. Define Process

|

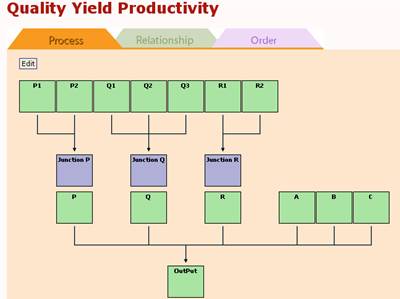

Define Process:

There are three simple steps in this stage.

Process:

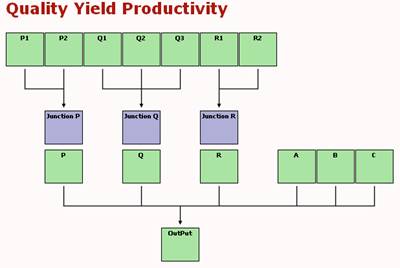

The Process tab allows the user to create a process for map of the production flow. Shown here for example, Process or Items P1 and P2 collect in Junction P and become one Process or Item of P. A junction is simply a point that has the total data for the processes before itself. Similarly, Process or Items P, Q, R and other straight Process or Items A, B and C are combined at Output. Most processes that be mapped like this may be suitable for QYP-ML.

|

|

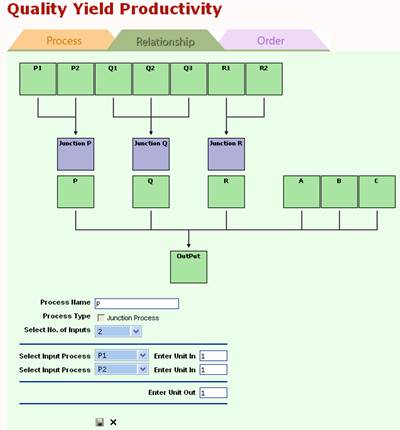

Relationship: In the Relationship step, the Relationships between the processes are constructed.

For example, for Junction P, Select No. of Inputs = 2 since there are two processes (processes P1 and P2). This information is entered in Select Input Process = P1 with Enter Unit In = 1; and the following line with Select Input Process = P2 with Enter Unit In =1. Lastly, Enter Unit Out = 1.

This relationship allows the user to indicate that 1 unit of P1 and 1 unit of P2 together give 1 unit of output. That is, 1 unit of P1 and 1 unit of P2 were somehow joined to give 1 unit of output.

Alternatively, had the values been that 1 unit of P1 and 1 unit of P2 give 2 unit of output, then that is equivalent to saying 2 units In and 2 units Out.

Suppose, 2 unit of P1 and 1 unit of P2 gave 2 unit Out. Presumably, 1 unit of P2 was sandwiched (or laminated) between 2 unit of P1 and the resulting part was cut into 2 units.

In fact, any other "reasonable" combination is possible. This relationship maintains the ratio of parts for calculating yields. |

|

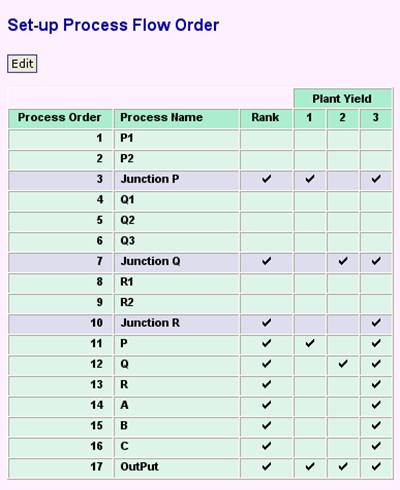

Order:

In the Order step, the Process Name and the Order in which graphs are to be plotted is set. Three settings of Plant Yield are available. For example, in Plant Yield setting 1, the Junction P, Process P and the Output are displayed. In setting 2, the Junction Q, Process Q and the Output is plotted.

|

3. Throughput

|

Throughput:

This tab allows the user to enter data into the tracking system. To enter data for a process point, the user only needs to click on the process points. Only the green squares can be clicked since the blue squares are the total of the processes below them and no data needs to be entered there. This graphical mode makes data entry very simple.

|

|

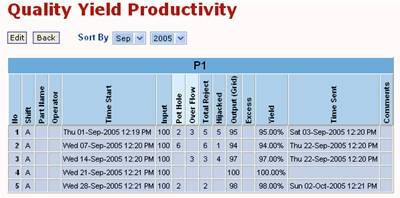

Clicking on a process (e.g. Process P1) brings up the data entry form. The user can enter data relevant to that process. Several defect types can be added.

|

4. By Date

|

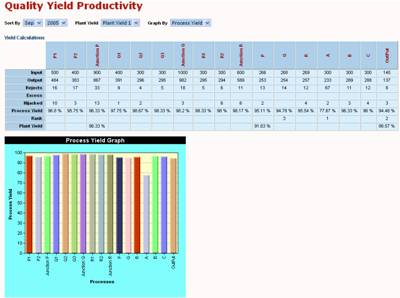

By Date:

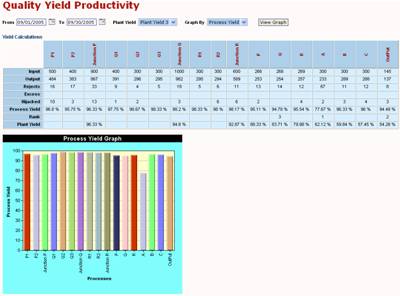

Once data has been added, several reports can be seen. This report shows the output at each process point between two dates for Process Yield based on Setting 1. |

|

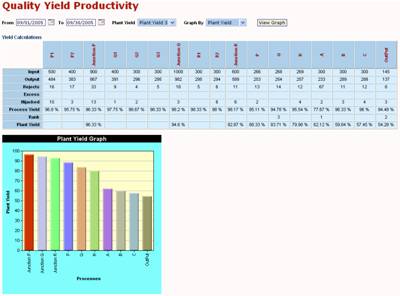

This report shows the output at each process point between two dates for Plant Yield based on Setting1

While not an ERP (Enterprise Resource Planning) system, QYP-ML provides an effective yet simple graphic system of quality, yield and productivity tracking.

|

5. By Month

|

By Month:

This report shows the output at each process point between two dates for Process Yield based on Setting 1. As for the By Date report, the user can also obtain the Plant Yield.

|

6. Process Performance

|

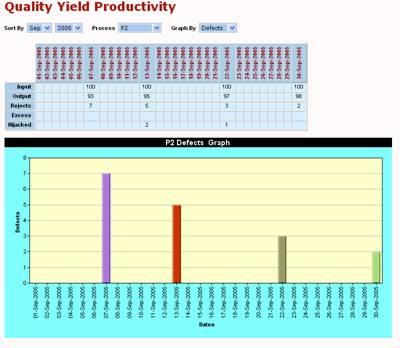

Process Performance:

This report can show many aspects of production. For a selected month, the user can choose the Process point and Graph By Input, Output, Defects, Excess or Hijacked.

|

7. By Date Report

|

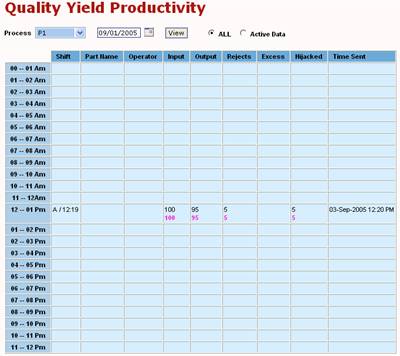

By Date Report:

This report shows the Process Output for any selected Process and Date. Active Data shows the results only for rows with data.

|

8. Product Report

|

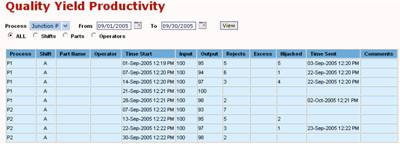

Product Report:

The Product Report provides a summary of the products made filtered according to the Process point and between selected From and To dates. |

|

|